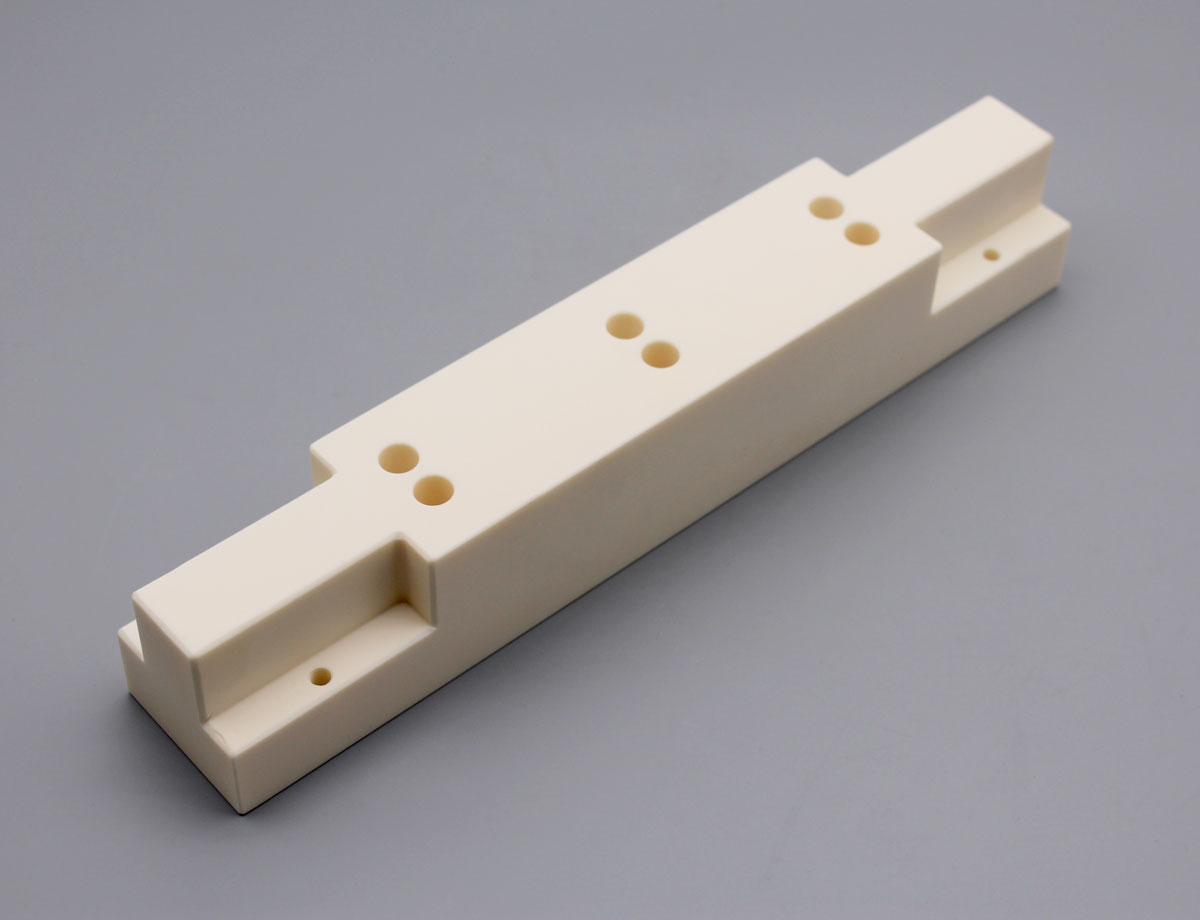

Ceramic Parts and Components

Ceramic guide pillar, ceramic part, alumina, gw ceramics, advanced ceramic, technical ceramic, Machinable ceramic parts, Machinable ceramic, precision ceramic

Silicon Carbide Ceramic Disc, Machinable ceramic part, gw ceramics, techniacal ceramic, advanced ceramic, Silicon Carbide, precision ceramic

alumina ceramic part, alumina, gw ceramics, advanced ceramic, technical ceramic, Machinable ceramic parts, Machinable ceramic, precision ceramic

Silicon Nitride Ceramic Nozzle, Silicon Nitride, ceramic parts, gw ceramics, advanced ceramic, technical ceramic, Machinable ceramic parts, Machinable ceramic, precision ceramic

Alumina Ceramic Ring, ceramic parts, alumina, gw ceramics, advanced ceramic, technical ceramic, Machinable ceramic parts, Machinable ceramic

Ceramic Wire Wheel, ceramic parts, alumina, gw ceramics, advanced ceramic, technical ceramic, Machinable ceramic parts, Machinable ceramic, precision ceramic

zirconia ceramic part, zirconia, gw ceramics, advanced ceramic, technical ceramic, Machinable ceramic parts, Machinable ceramic, precision ceramic, precision ceramic

Description

Ceramic parts are parts made by using materials such as alumina, zirconia, silicon nitride, silicon carbide and other materials through the process of forming and sintering. Typical ceramic parts include ceramic plates, ceramic rods, ceramic rings, ceramic sleeves, ceramic balls, etc. These products are highly precision and stable. Ceramic parts are more and more widely used in many fields, such as machinery, electronics, chemical industry, aerospace, communication, pharmaceuticals, etc. They are used to replace traditional parts made of plastics, metals and other materials, and to improve the overall performance of the equipment. GW Ceramics can customise all kinds of ceramic parts products according to the customer’s drawing requirements, and provide the customers with good products and services.

Properties

High strength: Advanced ceramic materials are very strong and ceramic parts have excellent physical properties.

Wear resistance: Compared to conventional materials, ceramic materials tend to be highly resistant to wear.

Anti-corrosion: Ceramic parts have excellent acid and alkali resistance due to advanced ceramic materials, which can resist the erosion of various strong acids and alkalis.

High precision: Ceramic parts are made of high-precision advanced ceramic materials and using a special process, so the product achieves high precision.

High temperature resistance: Ceramic parts can withstand high temperature and pressure, the material is not easy to deformation, aging.

Long service life: Ceramic component has 3-10 times longer life than metal component.

Applications

Machinery

Electronics

Chemical industry

Aerospace

Communication

Pharmaceuticals

Technical Information

Material Type:

Alumina

Zirconia

Silicon Nitride

Silicon Carbide

GW Ceramics provides customized services