Precision Metering Pump

Precision metering pumps, filling pumps, high speed filling, liquid filling, pharmaceutical filling, chemical filling, cosmetics filling, high viscosity liquid filling, paste filling

Precision metering pumps, filling pumps, high speed filling, liquid filling, pharmaceutical filling, chemical filling, cosmetics filling, high viscosity liquid filling

Precision metering pumps, filling pumps, high speed filling, liquid filling, pharmaceutical filling, chemical filling, cosmetics filling

Precision metering pumps, filling pumps, high speed filling, liquid filling, pharmaceutical filling, cosmetics filling, electrolyte filling

Precision metering pumps, filling pumps, high speed filling, liquid filling, pharmaceutical filling, cosmetics filling

Precision metering pumps, filling pumps, high speed filling, pharmaceutical filling, cosmetics filling, electrolyte filling

Description

Precision metering pumps are suitable for filling equipment with different needs. It can also work independently if users do not need multi-channel filling equipment. Precision metering pumps are widely used in food, cosmetic, pharmaceutical, new energy and packaging industries. Because of its high precision, high durability and high performance, it can effectively save materials for users and ensure users to produce stable and reliable quality products.

Working principle

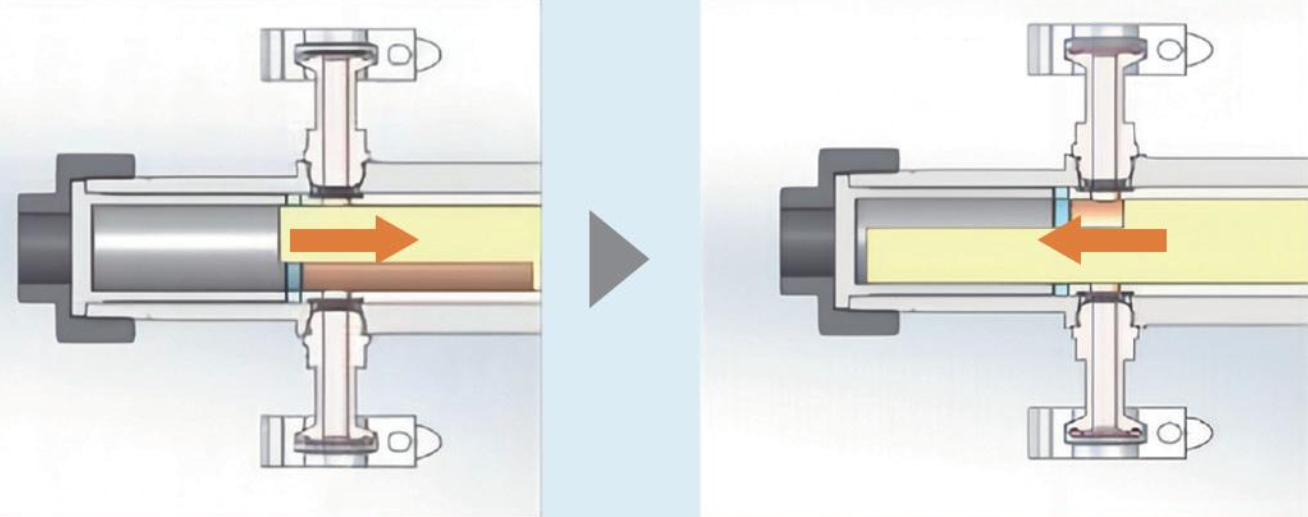

Check valve type: When the plunger contracts, it creates negative pressure in the pump chamber. The negative pressure causes the outlet check valve to close and the inlet check valve to open, filling the pump chamber with fluid. The amount of fluid drawn into the pump chamber is determined by the stroke of the pump plunger. During the fluid injection stroke, the plunger advances causing positive pressure in the pump chamber. This pressure closes the inlet check valve and pushes the outlet check valve open, allowing fluid to be discharged from the pump chamber. The volume of fluid is controlled by an adjustable micrometer stop that limits the stroke of the pump plunger. Servo position control models are also available. Check valve type pumps are ideal for clean fluids with low to medium viscosity and no particles.

Rotary valve type: Rotary valve pumps contain a slide valve to switch the fluid path from pump inlet to outlet. The suction stroke of the pump is accomplished by the rotary valve in the “inlet” position, allowing fluid to be drawn into the pump chamber. At the end of the suction stroke, the rotary valve rotates to the “outlet” position and then advances the plunger, which discharges the fluid. The volume of fluid is controlled by an adjustable micrometer stop which limits the stroke of the pump plunger. Servo position control models are also available. Rotary valve pumps are suitable for fluid of medium to high viscosity, containing particles.

Rotary piston valve type: Rotary piston pumps are designed with high-precision fit ceramic components, featuring seal-less operation without dynamic sealing. The pump mechanism consists of a rotary piston that moves within a precision-fit sleeve. During the suction stroke, the piston rotates, closing the outlet and opening the inlet. During the contraction of the piston, fluid is drawn into the pump chamber. At the end of the suction stroke, the piston rotates, thereby closing the inlet and opening the outlet. The volume of fluid is determined by the stroke of the ceramic piston. Rotary piston pumps are ideal for pharmaceutical, medical or cosmetic applications with cleaning and sterilization capabilities. Rotary piston pumps are capable of handling low to high viscosity fluids with or without particles.

Properties

High-precision metering: Filling accuracy can reach less than or equal to ± 0.5%.

Low maintenance: The structure and materials used in precision metering pumps are reliable and the user does not need to spend a lot of time and cost for maintenance.

High-speed cycling: While maintaining accuracy, precision metering pumps provide users with faster cycle speeds, increasing their productivity.

Precision speed and volume control: Work according to the user’s needs at all times.

Compact design: Precision metering pumps do not require a large site and are suitable for any size of equipment or production line.

Applications

Filling machines of various brands

Pharmaceutical Industry

Battery

Gel

Liquid

Cream

Syrup

Cosmetic

Chemicals

Other applications

Technical Information

Filling volume range: 0ml-2028ml

Filling accuracy: ≤ ±0.5%

Speed: 0-500cpm

Drive type: Pneumatic or electric

GW Materials provides customized services